Best Intelligent Intra-Logistics solution Provider in Coimbatore

As a top-notch AMR supplier, Goat Robotics stands as the best intelligent intra-logistics solution provider in and around Coimbatore, Tamil Nadu. We offer innovative technologies for seamless and efficient warehouse operations. Our solutions prioritize precision, adaptability, and innovation, ensuring optimal performance in diverse logistics environments. With a commitment to excellence, we deliver tailored and intelligent solutions that redefine intra-logistics for businesses.

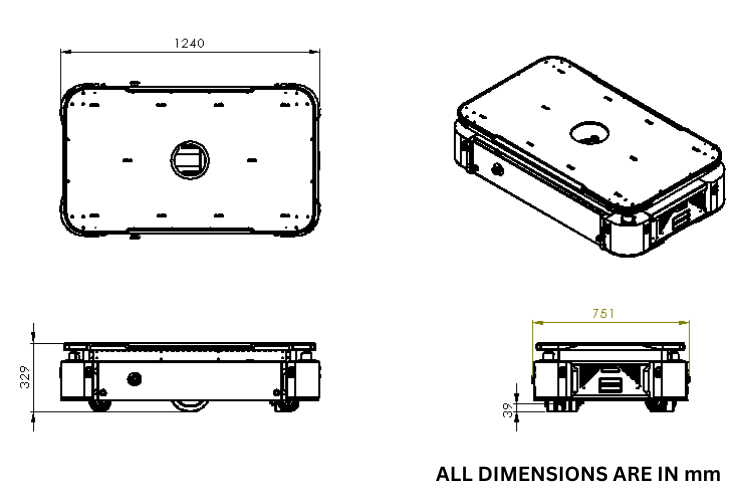

Goat Robotics is a leading manufacturer of intelligent intra-logistics solutions for the manufacturing and warehouse sectors. AMR brings cutting-edge technologies to optimize warehouse operations. Renowned for precision and adaptability, our manufacturing expertise extends to the production of the GTX 500, GTX 1000, and GTX 1500 series, each designed to redefine intra-logistics with innovative approaches. Choose Goat Robotics as your trusted partner to experience unparalleled excellence in intelligent solutions, revolutionizing your logistics landscape with the manufacturing process of GTX series robots.